Engineering

Across BFC, we are committed to delivering our customers engineered excellence. As part of the Tibbetts Group, we benefit from the investment and engineering expertise to guarantee quality parts for our customers.

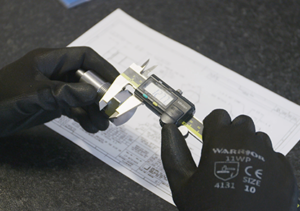

BFC fasteners and components undergo extensive testing including:

- Torque testing

- Full Laboratory Analysis

- Mechanical and chemical analysis

- Hardness testing

- Impact testing

- Non-Destructive Testing

Our specially selected and approved manufacturing partners work across the world to ensure quality assured products that meet stringent requirements.

Our highly skilled Engineering Team performs three key guarantees across our range of products including:

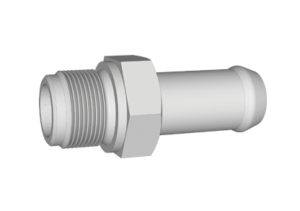

- Product Approval: All products are tested and verified against the required specifications and/or technical drawings

- Product Assurance: Allowing all mass-produced parts to be controlled to the pre-approved specifications and inspected on-site

- Product guarantee providing customers with product confidence, and a fantastic aftersales service

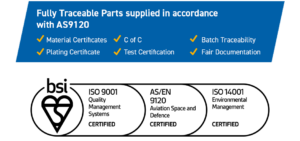

Aerospace Standards

All BFC Aerospace fasteners adhere to the relevant aerospace standards

from “Factory New” sources.

• NAS

• AN

• MS

• BACW

• BSA

• BAC

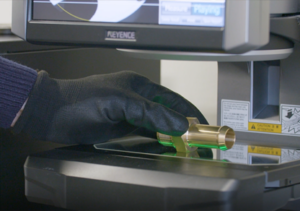

Sample Approval

• Pre-production approval and sign-off

• Sample library and documentation

• Customer confidence from the first order